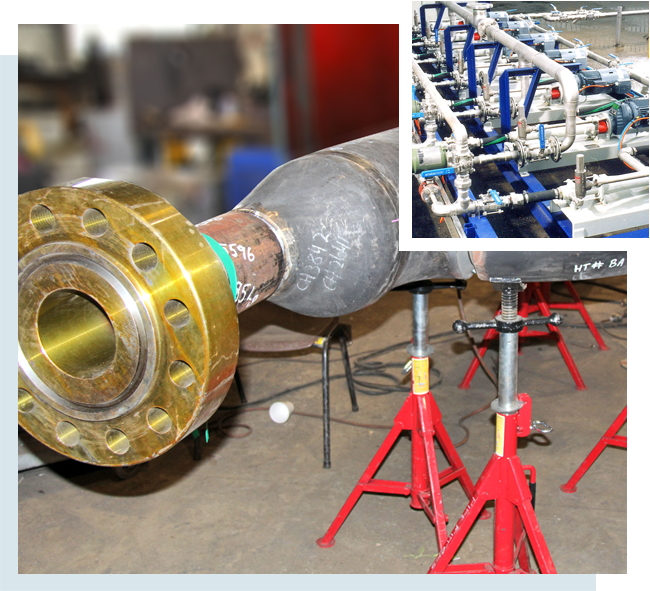

We Fabricate and carry out on-site installation and maintenance on various sites, and new industrial plants. Fabrication of piping, process pipe spooling, rubber lined spools, to Australian Standard (AS2885, AS4041) codes and also many International Standards.

Our workshop provides a contaminant-free environment (dedicated fabrication floor area) for fabrication of a wide range of materials including stainless steel & exotic materials and alloys such as 304, 316, duplex SAF 2205, super duplex SAF 2507, Copper Nickle as and when needed.

Western Engineering is equipped to scope, manage and execute the installation of welded process pipe and fittings onsite throughout Australia. Process pipe installation can include the installation of associated mechanical equipment such as pumps, valves and pressure vessels.

Safety and Health is a core value for Site Regional Services and is to all our planning and activities. We set ourselves high standards in health and safety and continuously strive to improve our performance in order to achieve our goal of Zero Harm.

To achieve business objectives, comply with legal obligations, exceed standards and satisfy the expectations of its clients and other stakeholders, Site Regional Services will manage and control risk as a means to maximising potential and minimizing the exposure to loss or harm.

To provide value and satisfaction to its customers. This will be achieved through systematic training and continual improvement of the quality management system, (IMS)in strict compliance with safety and legal requirements pertaining to its business.

SRS project delivery methodology shall be elaborated in detail through the following project delivery submittals during the project life-cycle, Project Execution Plan.

| Department | Personnel |

| Engineering Management | 6 |

| Administration | 2 |

| Document Control | 2 |

| HSE | 1 |

| Quality Assurance | 1 |

| Quality Control Inspectors | 1 |

| Engineering | 2 |

| Procurement | 2 |

| Manufacturing Personnel ;(Pipe Fitters, Fabricators, Coded Welders, Mechanical Fitters, Machinists, Supervisors, Riggers) | 20 |

| Current Number of Employees within the company | 97 |

Carry out Weld Specification in accordance with Global Requirements:

General Weld Specification Global Requirements: